Bolster Repair

Common with pull-through sharpeners. By digging in at the heel, they create an uneven blade shape. This limits the knife’s cutting ability since the entire blade can no longer contact the cutting board. This before and after picture shows how I was able to correct this problem and restore the knife’s proper shape and cutting ability.

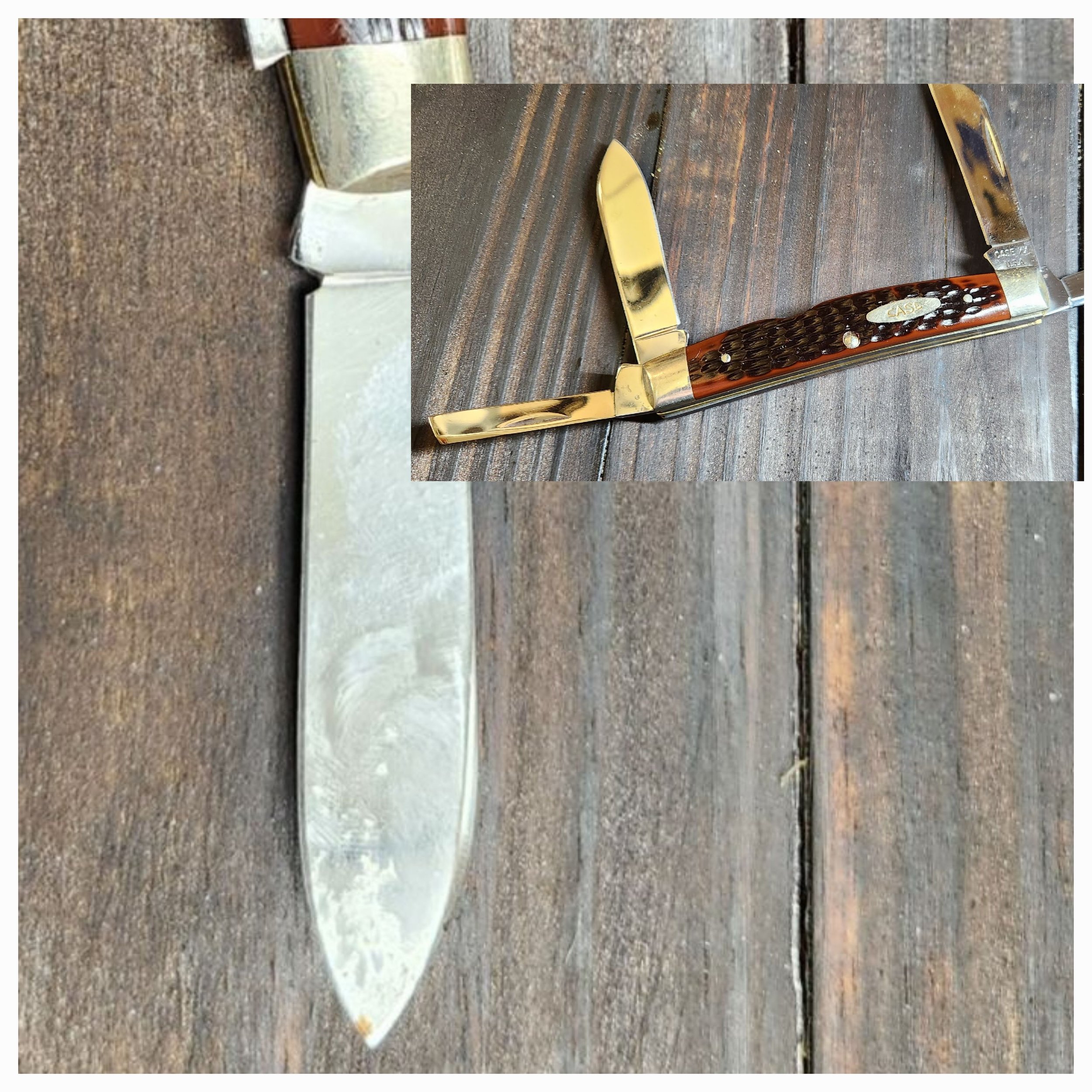

Tip Repair

The tips of knives can break for several reasons, but this doesn’t mean they can’t be fixed. This knife was a customer’s grandfather’s knife. It held a lot of sentimental value. I was able to restore its original shape and put a sharper than the new edge on it. I was told by the customer, that when he saw it, he cried for joy. One of the reasons I love doing this work is knowing what it means to someone when I can restore a part of their family history.

Fixing a Bent Tip

This knife had a bend in it. The smaller picture shows it straightened once again. I have a specialty tool that helps with this process.

Sharpening

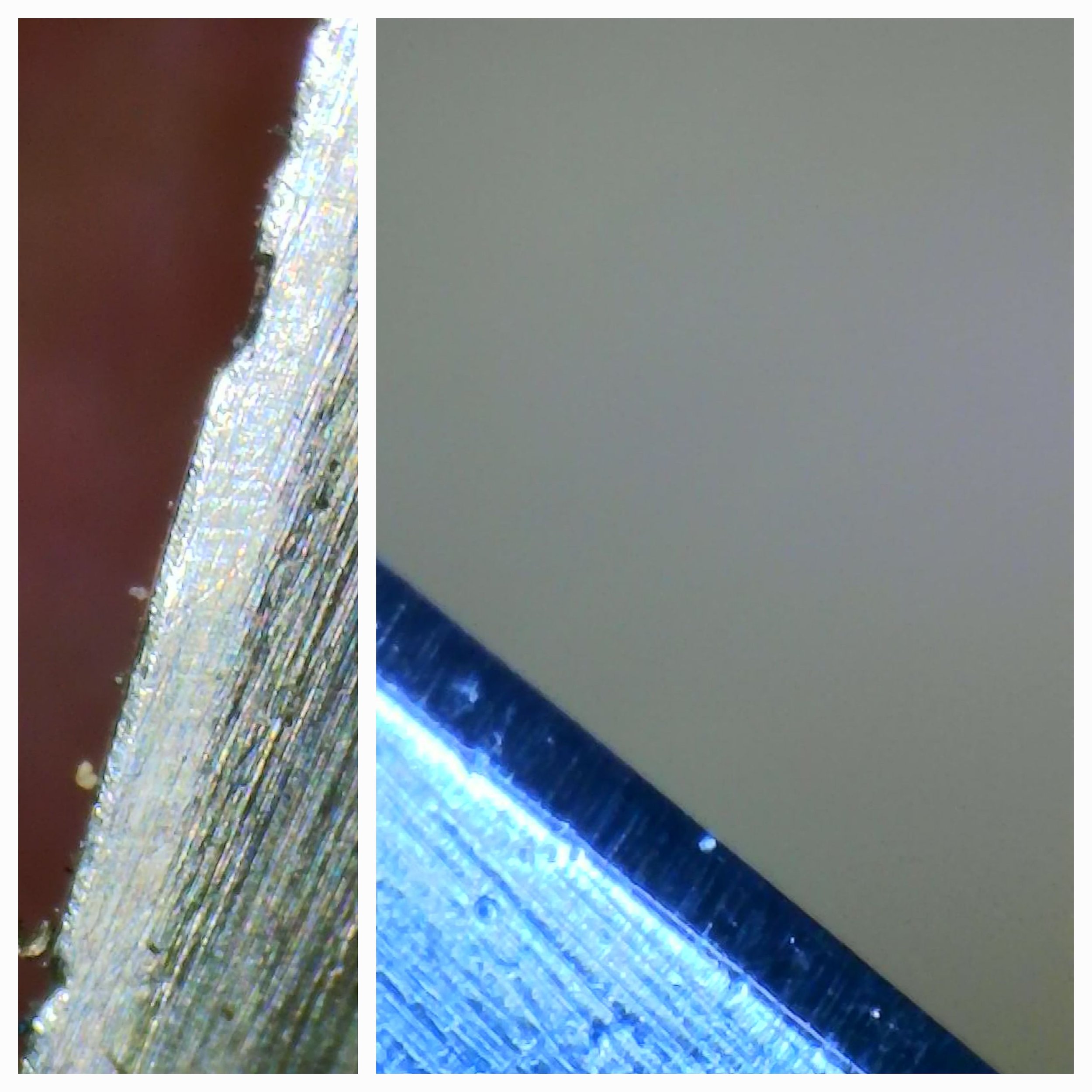

Sharpening is the process of resetting the bevel. Which sometimes includes getting past chips and other damage. This is followed by refining (honing) the edge and bringing it to meet at a fine point. Here is a microscopic before and after picture of a Shun paring knife. You can see chips and the use of a sharpening steel at the very edge. All of this made for a very dull knife. After sharpening, that same blade now has a smooth and even bevel. This creates a sharper than new edge. Even high-end knives often come from the factory with a relatively coarse and uneven grind.

This collage is another example. In the first two pictures, you can see the chips and the slightly broken tip. This too was very dull. The pictures with the darker background are after sharpening. By clicking on the video, you can also see what a knife is capable of after sharpening.

Shun Knife Cut Test

Highly Polished Edge

A polished edge takes quite a bit more work. Although it certainly isn’t necessary for a knife to work properly, it does increase the durability of the leading edge and adds an esthetically pleasing look to the knife. The high-end folder in the first picture received a polished edge that is razor sharp. The second is showing the mirror polish of the edge by reflecting the word “Amazing” off the paper.

Handles

Restoration and

Replacements

Handles can sometimes be restored to like new condition as with this vintage Chicago Cutlery or even replaced if needed.

Handle replacement

The wooden handles in this set had shrunk over the years. The cracks were filled in, the handles were sanded smoothly, and an oil finish was applied to restore the wood's original color.

The logo was missing on the back of this knife.. The hole was filled, sanded, and buffed smoothly to match the rest of the handle.

These handles were smoothed out and buffed to restore the color that had faded after being cleaned in a dishwasher for many years.

Custom Hunting Knife

Chisels with mirror polished edge

Mirror reflection of the flat back of the chisel

High end folder sharpened to a mirror polished razor sharp edge.

Remove scratches with satin finish

Remove scratches full polish

Axe Sharpening

Cut test of Estwing Wood Splitting Maul after sharpening.

Mower Blade

Mower blade cut test after sharpening.

Sharpened and properly balanced lawn mower blades not only cut grass better, but help the mower run smoother, and make the engine last longer.

Garden Tools

Vintage grass shears. Before and after pictures. Cleaned up and sharpened.

Pruner blade sharpening

Small chipper blades

I cleaned up, sharpened, and oiled this machete for a customer. It also brought the nice walnut handle back to life.